Ethylene copolymer modified asphalt resin (ECB-103)

key word: Polymer resin particle system

Product Details

ethylene copolymer modified asphalt resin (ECB-103)

★Product Introduction

Ethylene copolymer modified asphalt (ECB) resin is a high molecular weight thermoplastic random polymer produced by blending ethylene, vinyl acetate copolymer and asphalt resin by high pressure method.

★Product form

1. Color: black 2. Shape: round and granular.

★Product Performance

1.ECB-103 has good flexibility, toughness, low temperature resistance, weldability and compatibility with other resins.

2.ECB-103 has good fluidity, easy molding and processing, and can be extruded and blow molded.

Q/0222SDK 003-2012

|

ProjectItem |

ECB-103 |

|

VA content% |

14±1 |

|

Bitumen soluble content% |

≤8 |

|

Density (g/cm3) |

0.92~0.94 |

|

Shore hardness A |

85-90 |

|

Tensile strength MPa |

≥18 |

|

Elongation% |

≥ 750 |

|

Brittleness temperature ℃ |

-35 |

|

Melting point ℃ |

135±2 |

★ECB-103 recommended extrusion molding conditions (for reference only)

|

Project |

Temperature range |

Project |

Temperature range |

|

Rear of barrel |

150-160 ℃ |

Mold middle |

180-190 ℃ |

|

Middle part of barrel |

160-190 ℃ |

Mold left end |

190-200 ℃ |

|

Cartridge front |

190-200 ℃ |

Right end of die |

190-200 ℃ |

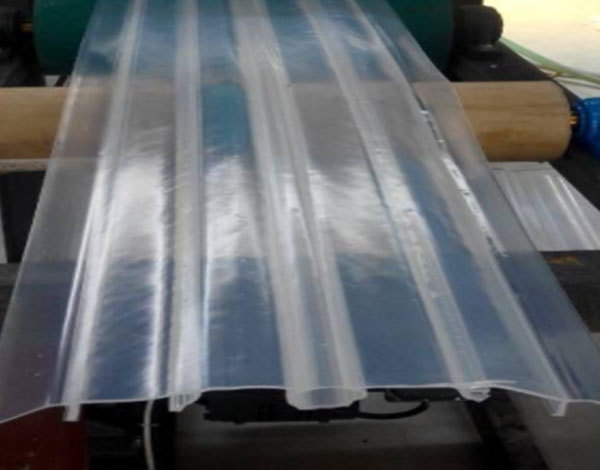

★Product application range

ECB-103 corresponding industries: construction water conservancy geotechnical plate products, petroleum asphalt modified special raw materials.

Hot Products

Product inquiry