PVC, EVA, ECB waterstop equipment

key word: Polymer waterproof equipment system

Product Details

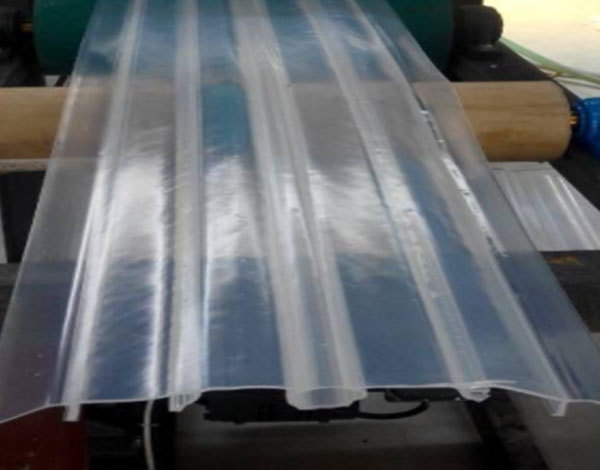

PVC, EVA water stop production line

1. Equipment introduction

The main selection of advanced PVC,EVA resin as the base material and a variety of fillers, through the planetary extrusion process made of new water-stop materials, unique design, advanced technology.

2. Equipment model

3. Process flow diagram

4. Technical parameters

The main engine adopts advanced variable speed technology, saving up to 30%.

The automatic heating system adopts thick mold circuit, saving about 40%.

1. Extruder SJ100 reducer SJY250 host power: 45KW

Extrusion barrel using 38CYMOALA material, nitriding screw heating power: 30KW/42KW

2. External heating power of mould: 23KW

3. Three roller machine roller surface for hard chrome processing power: 1.1KW

4. The traction machine adopts wear-resistant rubber roller, torque traction power: 10N

5. Meter J250-001 type transmission ratio: 1:3.3

6. Gas winding power: 0.75KW

5. Product introduction

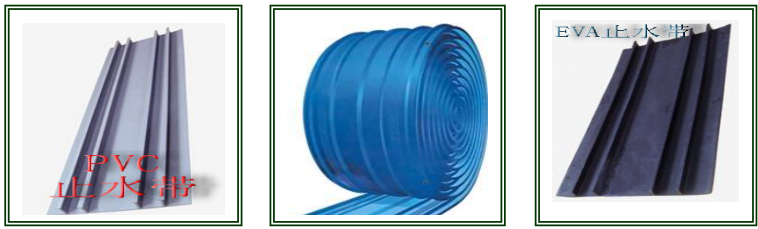

Production varieties: PVC water stop belt, EVA water stop belt (according to user needs processing custom-made various special models)

PVC,EVA water stop belt is made of polyvinyl chloride, EVA resin and various fillers, through special production process and made of water stop material. The product uses the elastic deformation characteristics of elastomer material to prevent leakage and seepage in the joint of building structure, PVC,EVA water stop belt and has the characteristics of corrosion resistance and good durability.

6. Product application scope

PVC, EVA water stop belt has a variety of different shapes, can be used in any ground or underground construction, forming a long and solid barrier, especially suitable for water storage and water retaining structure, such as reservoirs, sewage pools, dams, pools, subways, tunnel water retaining wall, etc.

Hot Products

Product inquiry