New era (3 2) intelligent integration TPO, HDPE self-adhesive waterproofing membrane production line

key word: Polymer waterproof equipment system

Product Details

New era (3 2) intelligent integration TPO, HDPE self-adhesive waterproofing membrane production line

1. Equipment introduction

Using elastomer TPO resin as the base material, through special extrusion and mold internal pressure shunt technology, the elastomer TPO rubber and plastic layer and the middle of the polyester or glass fiber reinforcement in one extrusion molding of the new surface-coated polymer waterproofing membrane. The unique coating on the surface of the coil makes the coil have a self-cleaning function, which effectively prevents the dust and pollutants in the air from damaging and coloring the coil. This equipment adopts the trinity (sub-surface coating intermediate enhancement layer TPO rubber and plastic layer) new production technology to produce the enhanced finished product three fusion, good compactness, not easy to peel, to a large extent, improve product quality, reduce energy consumption, and effectively control costs, improve production efficiency, in line with international standards.

2. Equipment model:

3. Technical parameters

Host adopts PLC technology, intelligent operating system.

The automatic heating system adopts thick mold circuit, saving about 40%.

1.1 extruder SJ165 * 2 reducer SJY375 * 2 host power: 160KW * 2

2. Extrusion die internal heating power: 38KW.

3. Three roller machine vertical roller surface for hard chrome processing power: 3KW

4. The traction machine adopts one steel and one glue, and the torque traction power is 16N

5. Steam expansion and winding power of coiler: 1.1KW/1.5KW

6. Self-adhesive coating system power: 96KW

Mold: the die adopts the international advanced expansion block fine-tuning technology, simple adjustment and uniform discharge.

★Product Description

Thermoplastic polyolefin (TPO) waterproofing membrane is a kind of acrylic rubber resin as the base material, the use of advanced polymerization technology and specific formula made of sheet thermoplastic rubber elastic waterproof material, is in recent years.

A new material popular in the United States and Europe, the ingredients do not contain plasticizers, there is no plasticizer migration and brittle. It has high tensile strength, good wear resistance, strong UV resistance, smooth surface, high reflectivity and

Comprehensive characteristics such as pollution resistance. Easy to process, can be welded, convenient construction, completely recycled, green new waterproof material.

★Type and specification

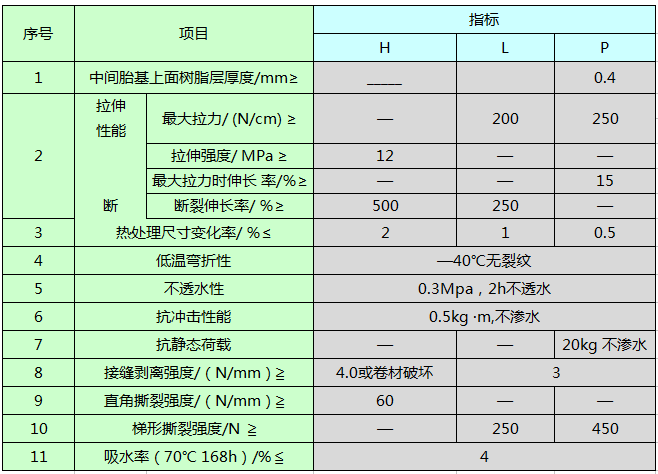

According to the classification of products, it is divided into: homogeneous non-composite coil (code H), composite coil with fiber backing (code L), and reinforced coil in fabric (code P)

Length: ≥ 20 m Width: 2.0 m

Thickness: 1.2mm 1.5mm 2.0mm

Color: black, white, green, etc., can be customized according to customer requirements (two-color coil can also be customized).

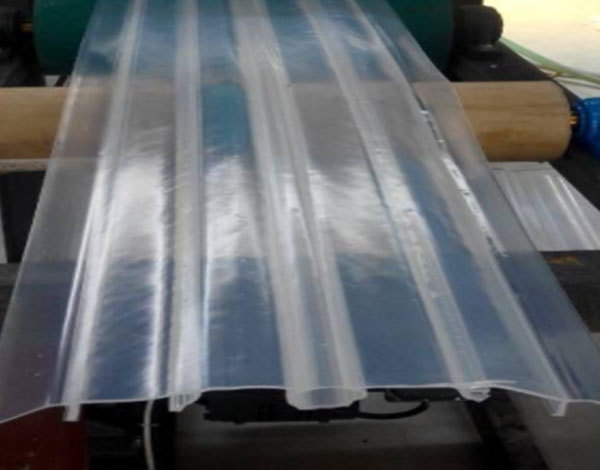

Product picture display

★Product performance GB27789-2011

★Product application range

Can be widely used in roof, basement, subway, dam, water conservancy, tunnel and steel structure roof, large supermarket and large factory building of permanent waterproof engineering.

Hot Products

Product inquiry