Polymer polypropylene, PVC waterproofing membrane production line

key word: Polymer waterproof equipment system

Product Details

High molecular weight polyethylene polypropylene, polyester, self-adhesive waterproofing membrane production line

1. Equipment introduction

This production line is made of PE (polyethylene) granular material (polypropylene or polyester cloth) and self-adhesive rubber by means of flat film extruder, which can replace the compound machine with secondary heating. The products produced by this equipment can not afford to drum, not warped edge, bond dense, stable performance, reliable quality, fully meet or exceed the GB18173.1-2006 and GB/T 23260-2009 standards. At the same time, the equipment also has the comprehensive advantages of high degree of automation, low power consumption, low labor and low cost of coil output.

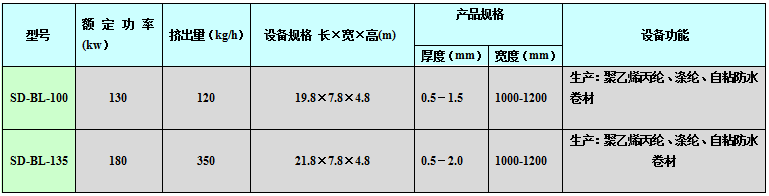

2. Equipment model

3. Technical parameters

The host adopts advanced variable speed technology, saving up to 30%

The automatic heating system adopts thick mold circuit, saving about 40%.

1. Extruder SJ100/135 reducer SJY250/315 host power: 45KW/90KW

2. Extrusion barrel using 38CYMOALA material, nitriding screw heating power: 30KW/42KW

3. Mold inside/outside heating power: 23KW

4. Three roller machine horizontal/vertical roller surface for hard chrome processing power: 1.1KW/1.5kw

5. traction machine adopts wear-resistant rubber roller, torque traction power: 10N.M

6. Meter J250-001 type transmission ratio: 1:3.3

7. Four-roller friction winding/air expansion winding power of coiler: 0.75KW/10N.M

8. Self-adhesive coating system power: 76KW

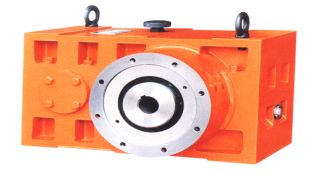

Reducer: reliable and durable, large overload capacity, low energy consumption, teeth

The surface of the wheel is specially treated for high wear resistance.

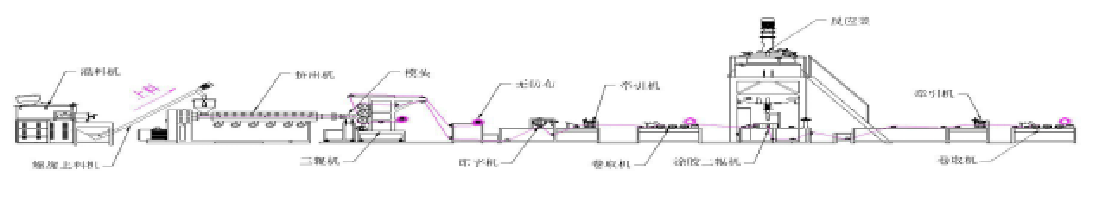

4. Process flow diagram

5. Product introduction

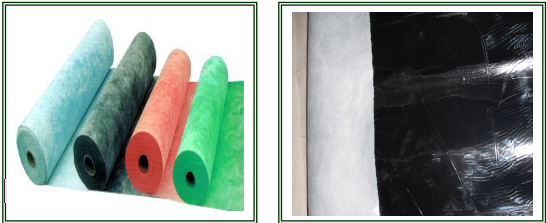

Production varieties:

High molecular weight polyethylene polypropylene fiber waterproofing membrane, high molecular weight polyethylene polyester waterproofing membrane, high molecular weight polyethylene polypropylene, polyester, self-adhesive waterproofing membrane.

High molecular polyethylene waterproofing membrane is polyethylene resin as the base material, double-sided with polypropylene cloth or polyester cloth and single-sided with self-adhesive rubber extrusion molding of polyethylene polypropylene composite waterproofing membrane or polyethylene polyester composite waterproofing membrane and self-adhesive polymer waterproofing membrane. This product has the advantages of wet roof construction, convenient operation, no pollution, etc.

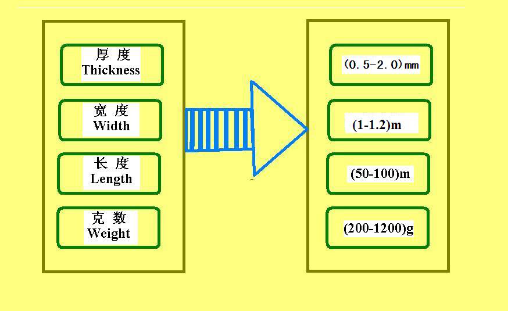

6. Product specifications

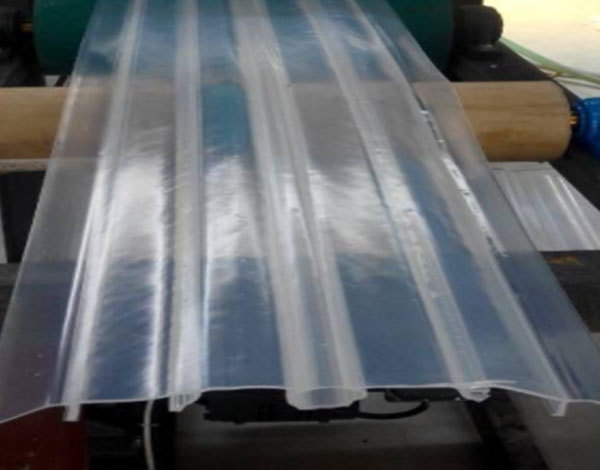

7. Product display

8. Product performance

High molecular weight polyethylene waterproofing membrane performance index

GB 18173.1-2006

9. Construction method

Acceptance of leveling layer → cleaning of base layer → preparation of cement adhesive or direct pasting → additional layer → construction of base layer → protective layer → curing

10. Product application scope

Various types of office buildings, commercial and civil residential building roofs, basements, toilets, water conservancy, grain depots, bridges and other anti-seepage and waterproof projects.

Hot Products

Product inquiry